No hay productos en la cesta

El glorioso podio en la Flecha Valona

Hay muchas formas de ganar, pero solo unas pocas son grandiosas. La miserable meteorología ha visto al enorme Van Gils cruzar la última línea en tercera posición.

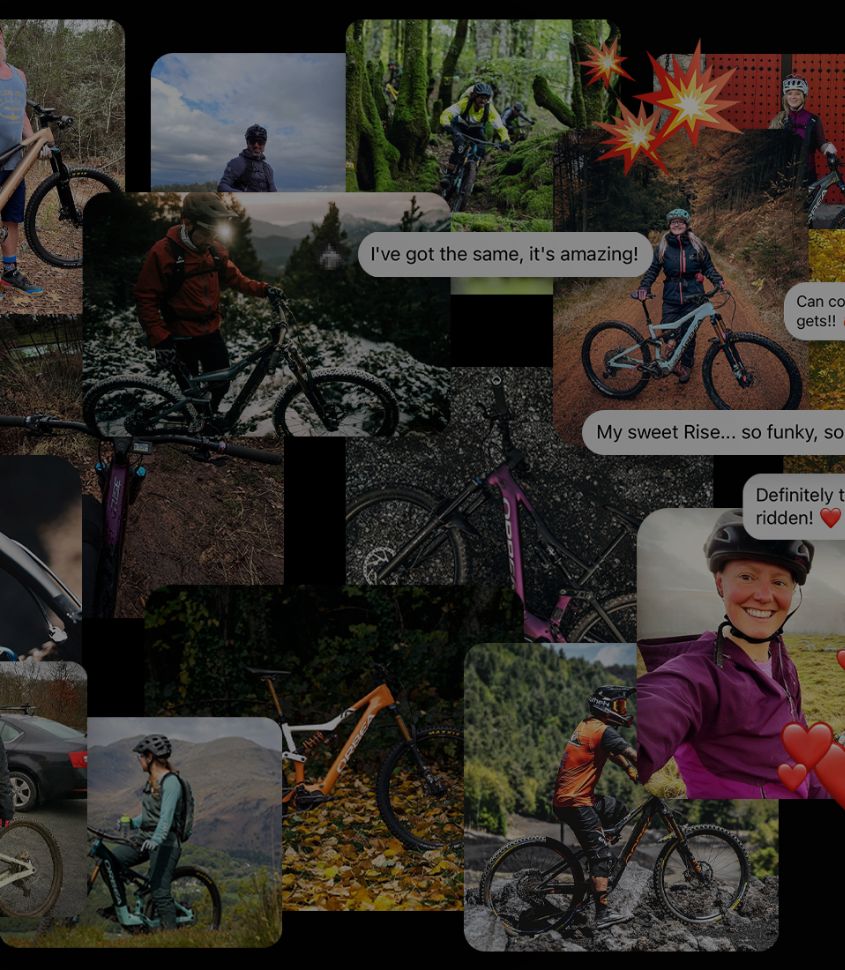

RISE ABOVE AND BEYOND

El lanzamiento de Rise revolucionó el trail riding. No pretendemos haber inventado las e-bike ligeras, tan solo cambiamos la manera de divertirse sobre un sendero.

The New A to B

Ir de A a B debería ser un placer, no un incordio. Diem es una bicicleta eléctrica urbana en la que puedes confiar y que añade un toque de clase a tu día a día. ¡Súbete a Diem y disfruta el día!

Modelos destacados

Esta es la selección de los modelos destacados actualmente, elige el que mejor se ajuste a tus necesidades.

-

OIZ M LTD

Nueva opción de Flight Attendant para Oiz M-LTD. Saca el máximo partido a tus suspensiones gracias al nuevo sistema de RockShox, ahora disponible como opción configurable.

-

DIEM 10 20mph

Diem 10, la potente bicicleta eléctrica urbana, se funde con tu actividad cotidiana haciendo cada desplazamiento aún más fácil, gracias al cambio automático Enviolo y la transmisión por correa, ambos sin mantenimiento.

-

-

DIEM 30 20mph

Diem 30, una potente bicicleta eléctrica urbana, hace que cada desplazamiento sea un auténtico placer gracias a sus 9 velocidades y a nuestra ligera batería de 540 W.

-

-

Adventure²

Oiz M-LTD ahora equipada con el nuevo RockShox Flight Attendant

Take it too far

Design your ride

OC COMPONENTES

COMPARTIENDO HISTORIAS

Entretenimiento e información útil en torno a nuestra marca y a la afición que nos une: el ciclismo.

-

Un día difícil en Gante-Wevelgem.

Leer artículo

-

Lotto-Dstny se despide de Italia tras una excelente actuación en Milán-San Remo

Leer artículo

-

¡Empieza la aventura! Cobertura en vivo desde la Cape Epic

Leer artículo

-

LOS EQUIPOS ORBEA AFRONTAN LA 20ª CAPE EPIC

Una vez más los equipos Orbea XC apuntan alto en esta temporada 2024. Cuando se afrontan objetivos, apenas hay ninguno tan monumental como Cape Epic.

Leer artículo

-

Orbea y Lotto Dstny: Uniendo fuerzas en una nueva era

Personas, pasión y rendimiento: como Orbea y Lotto Dstny unimos fuerzas para afrontar las competiciones más exigentes del mundo.

Leer artículo